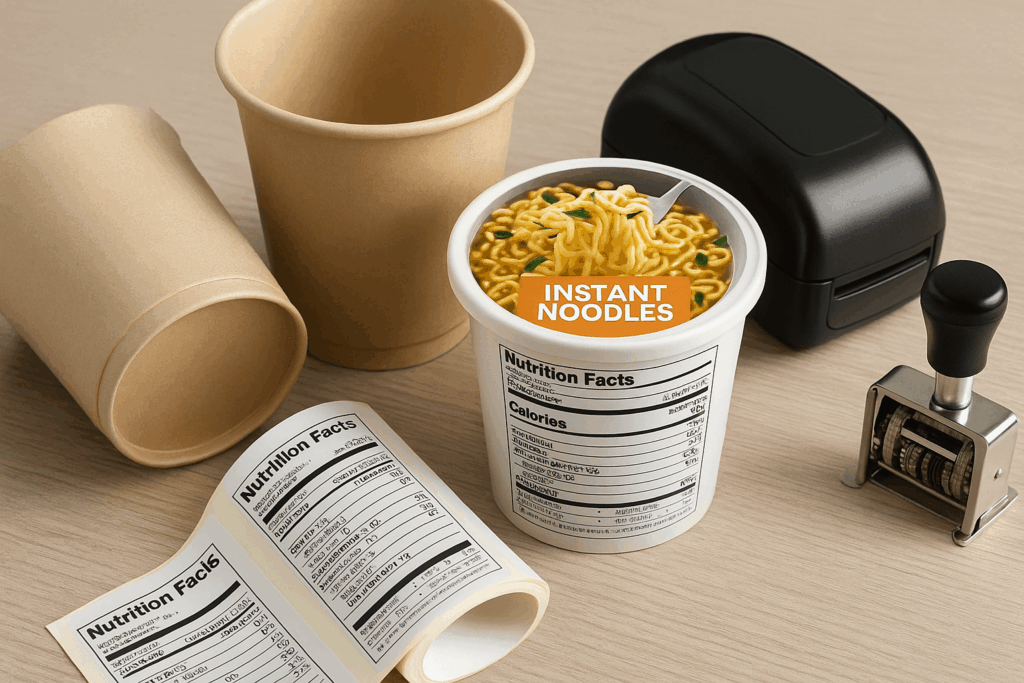

If you’re planning to launch your own instant noodle brand, one of the first major decisions you’ll face is:

Should you manufacture in-house, or work with a private label OEM partner?

At Kimdee, we help food brands scale faster and smarter by offering private label instant noodle manufacturing — giving them full control over product quality, brand identity, and go-to-market speed, without the burden of running their own factory.

Here’s a clear breakdown to help you decide.

✅ 1. What Is Private Label Manufacturing?

Private label manufacturing means you partner with an established food producer to manufacture your product — under your brand name — based on your specifications.

You control:

Branding

Recipe design (optional)

Packaging and marketing

The OEM partner (like Kimdee) controls:

Ingredient sourcing

Production and quality control

Export logistics and certifications

👉 Learn how Kimdee supports private label instant noodle development

✅ 2. What Is In-House Manufacturing?

In-house manufacturing means you build or buy your own production facility.

You manage everything: sourcing, staffing, certifications, equipment maintenance, food safety audits, and compliance.

While it offers complete control, it also demands:

Huge upfront capital investment (millions USD)

Technical expertise in food production

Management of operational risks and recalls

In short: higher control, but higher complexity and financial risk.

✅ 3. Private Label vs. In-House: Key Comparison

| Factor | Private Label (OEM) | In-House Manufacturing |

|---|---|---|

| Capital Investment | Low | Very high (factory, machines, licenses) |

| Time to Market | 2–4 months | 1–3 years minimum |

| Quality Control | OEM manages (certified) | You manage (needs expertise) |

| Flexibility | High (pilot batches, fast scaling) | Low (fixed equipment limits) |

| Risk | Shared | 100% on you |

| Focus | Branding & sales | Factory operations |

✅ Private label is the best option if your focus is brand-building, marketing, and customer relationships — not running factories.

✅ 4. Why Brands Choose Private Label with Kimdee

Low MOQ: Start from 10,000 units, perfect for testing new markets.

Custom Recipes: Develop your own flavors (vegan, low sodium, high-protein).

Export Compliance: We handle HACCP, ISO, BRC certifications for global markets.

Packaging Support: Create compliant, premium branding for different regions (EU, US, UAE).

Faster Scaling: Pilot > market test > scale, all with one partner.

Kimdee acts as your outsourced factory — so you can focus on growing your brand faster and leaner.

📩 Want to launch your own private label instant noodle brand without factory headaches?

Contact us at carlng@kimdeefoods.com

🔗 Start your project here

❓ Frequently Asked Questions (FAQ)

Q1: Can I customize my recipe with a private label manufacturer?

A: Yes. At Kimdee, we offer full formula development — whether you want vegan, low sodium, no MSG, or special flavor profiles.

Q2: How fast can I launch using a private label model?

A: Typically within 45–60 days from initial consultation to first shipment.

Q3: Will Kimdee help with export documents and compliance?

A: Absolutely. We manage all necessary export certifications and shipping logistics.